/Stainless steel/Stainless steel welded tubes

STAINLESS STEEL WELDED TUBES

round and box sections

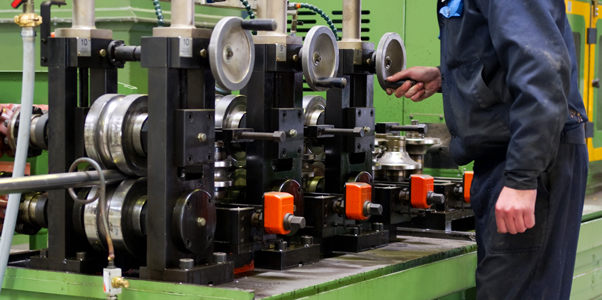

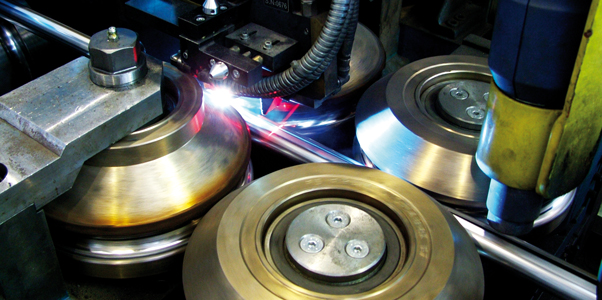

Stainess steel process pipes for food & dairy industry, tubes for heat exchangers and oil & gas, but also construction and ornamental tubes and box sections, as well as tubes for mechanical and automotive applications: with a global production covering all major sectors, Marcegaglia is the world’s top producer of stainless steel welded tubes.

The fabrication process is carried out within 4 manufacturing units worldwide, guaranteeing the same quality levels of products and service and totalling about 400 thousand tons overall capacity.

In Italy Marcegaglia Forlì, the world’s largest stainless steel tube manufacturing unit hosts 33 tube mills and operates according to certifications including ISO/TS 16949 for the automotive sector as well as DVGW for water and gas pipes, TÜV-PED / TÜV AD-2000 for pressure equipment, TIFQ for food contact (EC Regulation 1935/2004) and EHEDG for hygienic equipment design criteria. Welding processes are also certified according to ISO 3834-2.

Outside Italy, Marcegaglia stainless steel production is located in the plants of Marcegaglia Russia in Vladimir, Marcegaglia Turkey in Istanbul and Marcegaglia do Brasil in Garuva.

Specific production norms are employed according to EN or ASTM for specific application sectors:

- process pipes for fluids

- feedwater heater tubes for power plants

- construction and ornamental tubes

- tubes for mechanical and automotive applications

PROCESS PIPES FOR FLUIDS

| MANUFACTURING STANDARD | PRODUCT DESIGNATION |

| EN 10357 EN 10217-7 ASTM A270 |

Process pipes for the foodand dairy industry |

| EN 10217-7 DVGW GW541 |

Process pipes for drinkable water and press fitting |

| EN 10217-7 EN 10312 |

Process pipes for water treatment |

| EN 10217-7 | Process pipes for the pulp and paper sector |

| EN 10217-7 AD 2000 W2/W10 PED 2014/68/EU |

Process pipes for chemical applications |

| EN 10217-7 DIN 11866 |

Process pipes for pharmaceutical applications |

| EN 10217-7 ASTM A312/A778 |

Process pipes for oil and gas applications |

MECHANICAL APPLICATIONS

| MANUFACTURING STANDARD | PRODUCT DESIGNATION |

| EN 10296-2 EN 10217-7 |

Round tubes for pumps and cylinders |

| EN 10217-7 | Round tubes for elbowsand fittings |

| EN 10217-7 | Round tubes for heat resistances |

HEAT TREATMENT

| MANUFACTURING STANDARD | PRODUCT DESIGNATION |

| ASTM A 803 A 803M ASTM A688 A 688M |

Ferritic feedwaterheater tubes Austenitic feedwater heater tubes |

| EN 10217-7 ASTM A249 AD 2000 W2/W10 PED 2014/68/EU |

Round tubes for heat exchangers |

| EN 10296-2 EN 10217-7 |

Round tubes for evaporators for the sugar industry |

| EN 10217-7 AD 2000 W2/W10 |

Round tubes for pressure vessels |

| EN 10217-7 | Tubes for boilers |

CONSTRUCTION

| MANUFACTURING STANDARD | PRODUCT DESIGNATION |

| EN 10296-2 round only ASTM A554 |

Construction round tubes and box sections |

ORNAMENTAL

| NORMA DE FABRICATION | PRODUCT DESIGNATION |

| EN 10296-2 round only ASTM A554 |

Ornamental round tubes and box sections |

AUTOMOTIVE

| MANUFACTURING STANDARD | PRODUCT DESIGNATION |

| EN 10296-2 ASTM A554 |

Round tubes for automotive, exhaust systems |

| EN 10296-2 ASTM A554 |

Round tubes for automotive, hydroforming appliance |

| EN 10296-2 round only ASTM A554 |

Round tubes and box sections for automotive frame construction |

Thanks to its production know-how, Marcegaglia Specialties is able to process

|

Optional controls and processing for Marcegaglia product range of stainless steel welded tubes.

Standard and optional testing

- Chemical composition

- Micrographic analysis

- Tensile test at room temperature or other temperature

- Flattening test

- Expansion test

- Radial expansion test

- Bending test

- Electromagnetic test

- Non destructive eddy current weld test

- Dimensional test

- Visual test

- Surface roughness measurement

- Salt spray test

- Test for corrosive traces

- Intergranular corrosion test

- Potentiostatic corrosion test

- Grain size measurement

- Ferrite measurement

- Burst test

- Humidity test

- Release of special certificates

Optional processing

- Heat treatments

- Pickling

- Outer surface brushing

- Inner and outer surface polishing

- Inner and outer surface mirror polishing

- Tubes individually sleeved

- Bead rolling or weld seam removing

- Cut to length

- Customer defined marking

- Customer defined tolerances

- Welding position (box sections)

- Special packaging

| Min – Max Outside diameter (mm) | 6 – 406,4 |

| Min – Max Thickness (mm) | 0,8 – 6 |

|